OUR BAT MAKING PROCESS

CUSTOMISING CRICKET BATS FOR EVERY PLAYER

Our process is uniquely our own. Rod Grey is completely self-taught and it has been years of refinement to get our shapes and processes right.

The cricket bat industry is very interesting in that there is no one way of "how to do it", especially in Australia. When Rod first started, there was little information online, so alot of mistakes were made, lots trial and error was needed but in the end we strive to produce a product that allows the user to have the ultimate flexiblility in choosing a bat that is just right for them.

The process is simple, customise each individual bat for each individual player.

Below is our process.

We only use genuine English willow to make cricket bat out of. England has the best climate to grow the willow in and nothing else compares.

We use all grades of willow to make cricket bats from as not every player needs or wants the top shelf grade of willow.

Each player has a different story. This is developed by how they learnt their techinque, players they grew up wanting to be and the personality of the player in general.

We have a large range of different shapes that we can recommend to players that will suit their style.

Once this has been decided, we talk about the weight that we would like to acheive to ensure we choose the right cleft before we start shaping.

We use CNC technology to preshape all of our clefts to ensure that we offer very consistant shapes no matter the size or weight we are trying to acheive.

All of the shapes are designed in house which gives us ultimate control over the profiles. It also allows us to match ANY bat shape possible.

We use our awesome splice and handle cutting saw to get a perfect fit between blade and handle every time.

We turn our own handles in our workshop so we can provide industry leading customisation in this area.

Thickness options of thin, standard, thick and ultra thick. Shape options of round, semi oval and oval. Length options of super short, short and long.

We can even make completely custom shape handles for particular players aswell.

Once the pre-shaping is complete and the handle is set we finalise the shape by hand using traditional wood working tools including hollowing planes, drawknives, heal shaves, travishes and spokeshaves.

Toes shapes are really a personal preference and we offer these in round, square and ultra round.

Sanding, sanding, sanding!

Making cricket bats requires alot of sanding. Our cricket bats go through 3 stages of sanding to give them a great finish ready for polishing.

Once the sanding is complete the polishing process begins.

We polish the bat until it has a nice smooth finish with a hint of glossiness to it to show off the grains of the English Willow.

The handle must get bound to the blade to help keep the joint secure while it hits 1000's of balls each season.

We use a premium binding to ensure a great feeling under the grip.

We offer toe protection in the form of Shoe Goo and our unique Hard Toe. Both offer great protection from moisture and protect the toe from the rigors and training in particular.

Shoe Goo is a liquid rubber that gets appiled the the toe and we ensure that it goes over the egdes to encase the etire toe of the bat.

Hard Toe is a polyurethane Resin that is impact resistant and will flex with the cricket bat.

Face protection is a great addition to any cricket bat. We offer 3 types.

Clear Guard which has a soft, matt feel to touch and also has self healing properties to ensure it doesn't tear or crack over time.

Clear Guard with fibre edging is the same as Clear Guard with the addition of Fibreglass tape on the edges for extra edge protection.

Fibre Guard is an entire Fibreglass tape layer applied to the cricket bat for reinforced protection across the face and edges.

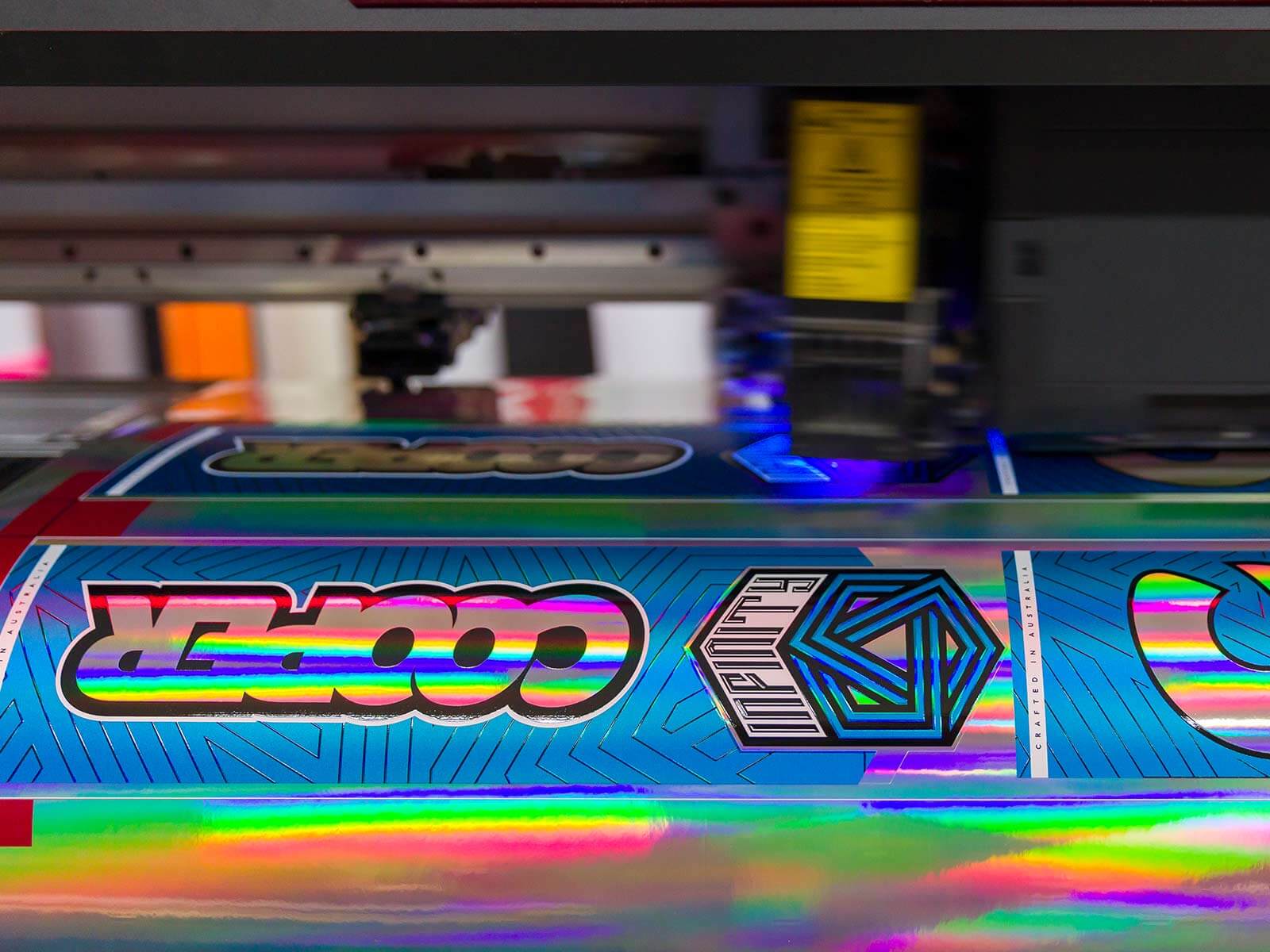

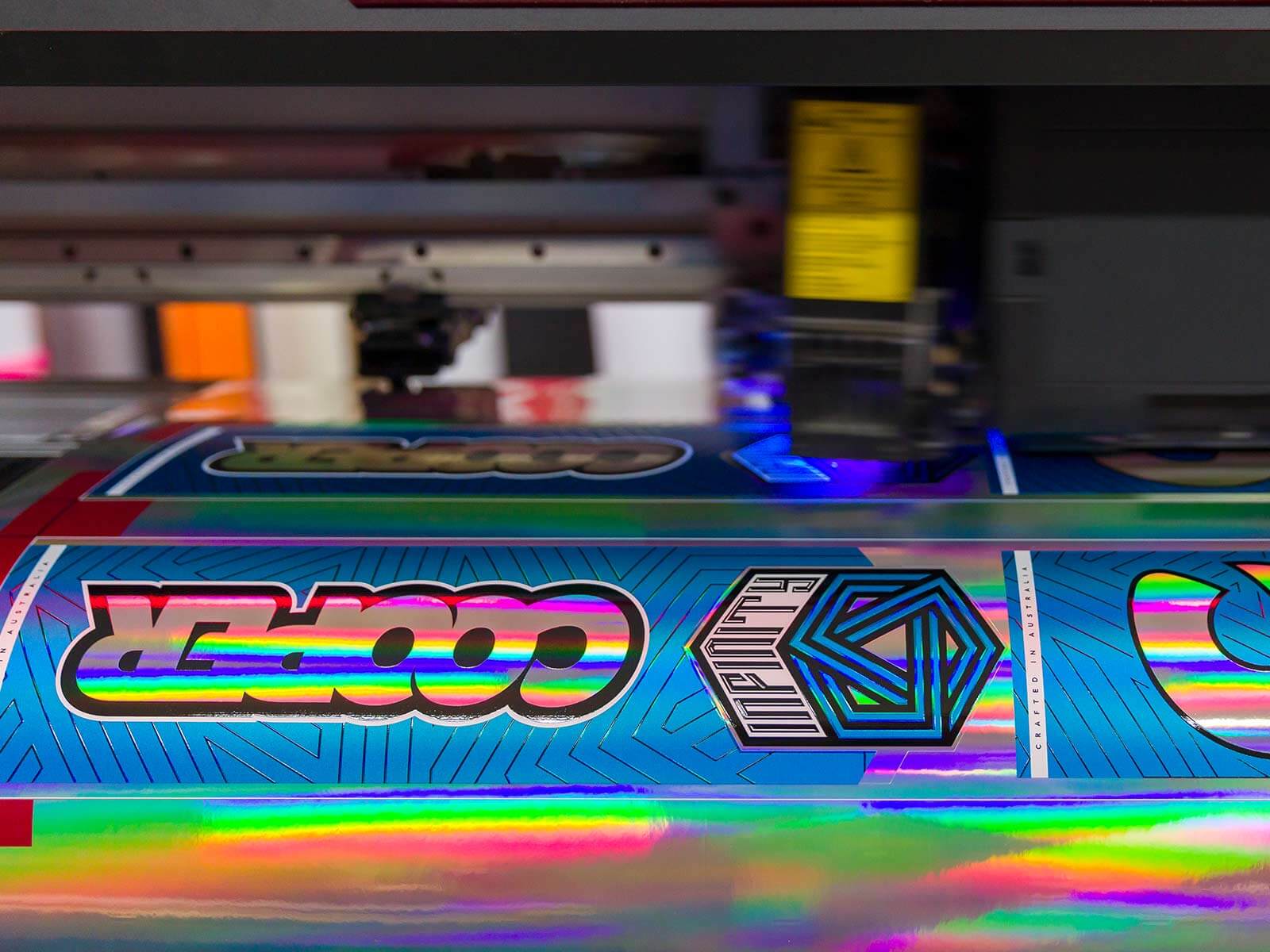

Our stickers are unique to us as we make them in-house.

Our UV printing technology mixed with premium vinyls ensure a eye catching finish.

We can even custom make stickers that are unique to your cricket bat.

You can personalise your cricket bat by adding some impressive laser engraving into the face, the back, the edges or where ever you want!

Great for adding initials, a name or some motivational wording.

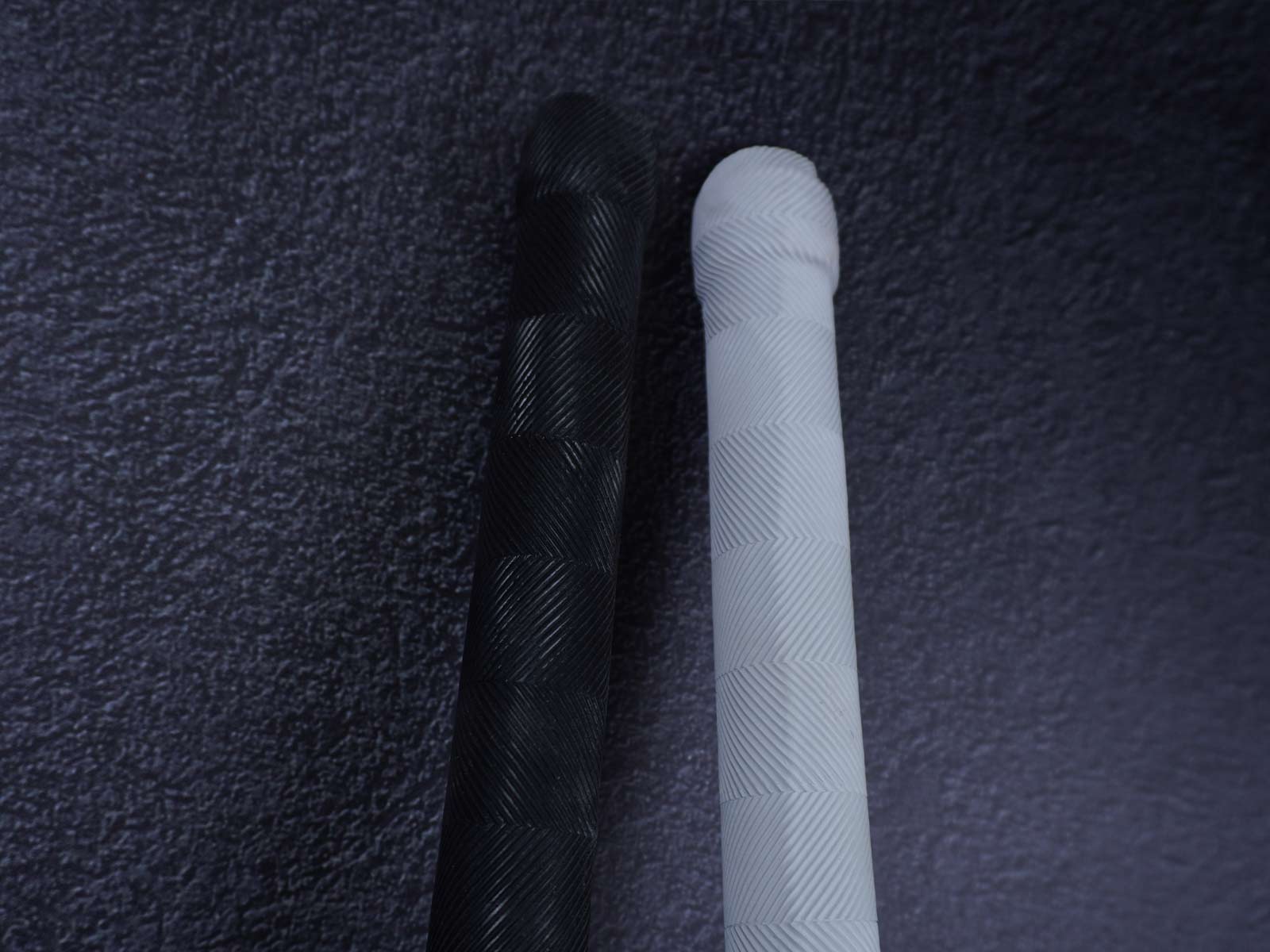

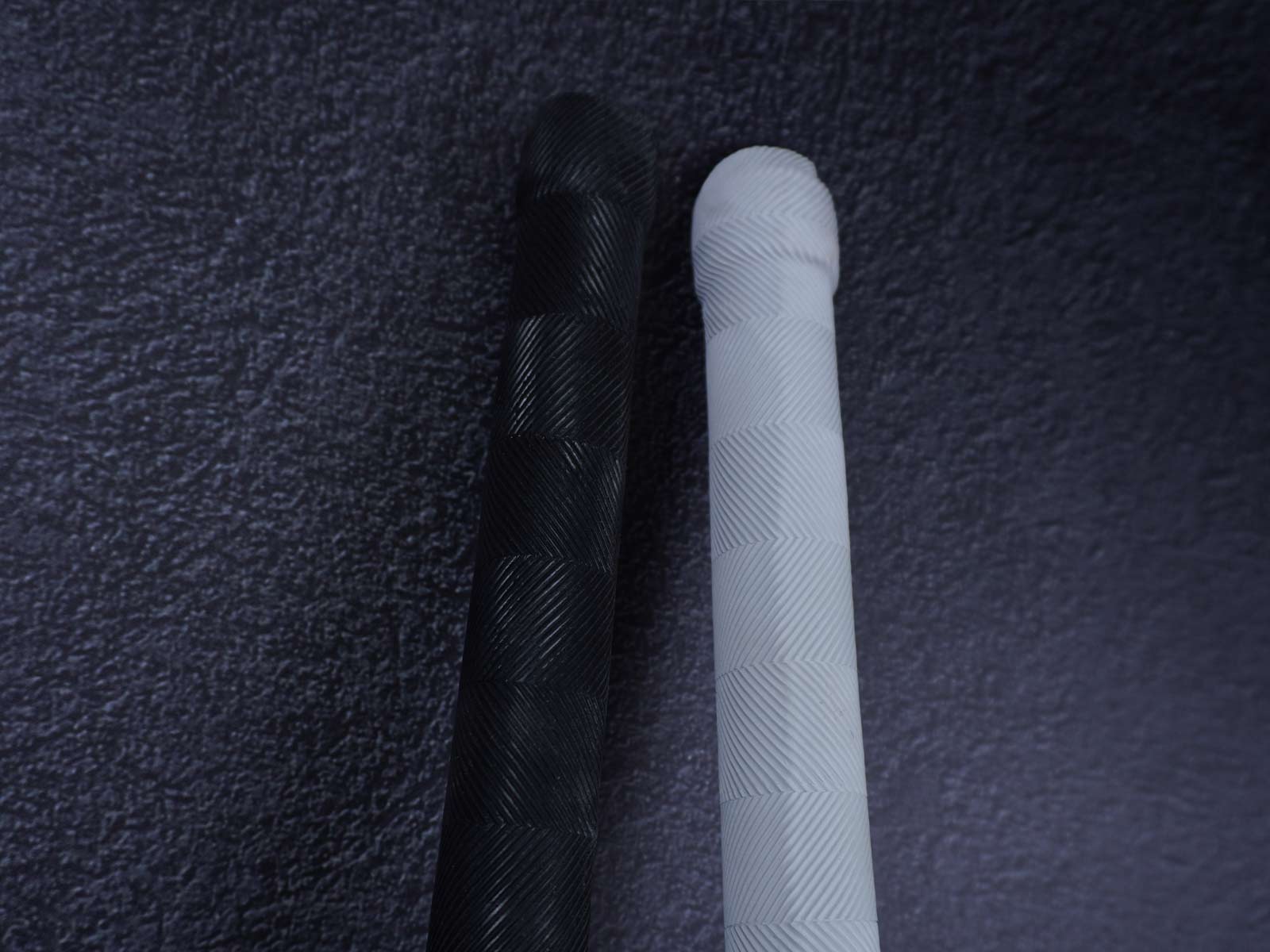

All bats come with either a white or black chevron grip.

We use these grips as they are super durable and very grippy!

We only use genuine English willow to make cricket bat out of. England has the best climate to grow the willow in and nothing else compares.

We use all grades of willow to make cricket bats from as not every player needs or wants the top shelf grade of willow.

Each player has a different story. This is developed by how they learnt their techinque, players they grew up wanting to be and the personality of the player in general.

We have a large range of different shapes that we can recommend to players that will suit their style.

Once this has been decided, we talk about the weight that we would like to acheive to ensure we choose the right cleft before we start shaping.

We use CNC technology to preshape all of our clefts to ensure that we offer very consistant shapes no matter the size or weight we are trying to acheive.

All of the shapes are designed in house which gives us ultimate control over the profiles. It also allows us to match ANY bat shape possible.

We use our awesome splice and handle cutting saw to get a perfect fit between blade and handle every time.

We turn our own handles in our workshop so we can provide industry leading customisation in this area.

Thickness options of thin, standard, thick and ultra thick. Shape options of round, semi oval and oval. Length options of super short, short and long.

We can even make completely custom shape handles for particular players aswell.

Once the pre-shaping is complete and the handle is set we finalise the shape by hand using traditional wood working tools including hollowing planes, drawknives, heal shaves, travishes and spokeshaves.

Toes shapes are really a personal preference and we offer these in round, square and ultra round.

Sanding, sanding, sanding!

Making cricket bats requires alot of sanding. Our cricket bats go through 3 stages of sanding to give them a great finish ready for polishing.

Once the sanding is complete the polishing process begins.

We polish the bat until it has a nice smooth finish with a hint of glossiness to it to show off the grains of the English Willow.

The handle must get bound to the blade to help keep the joint secure while it hits 1000's of balls each season.

We use a premium binding to ensure a great feeling under the grip.

We offer toe protection in the form of Shoe Goo and our unique Hard Toe. Both offer great protection from moisture and protect the toe from the rigors and training in particular.

Shoe Goo is a liquid rubber that gets appiled the the toe and we ensure that it goes over the egdes to encase the etire toe of the bat.

Hard Toe is a polyurethane Resin that is impact resistant and will flex with the cricket bat.

Face protection is a great addition to any cricket bat. We offer 3 types.

Clear Guard which has a soft, matt feel to touch and also has self healing properties to ensure it doesn't tear or crack over time.

Clear Guard with fibre edging is the same as Clear Guard with the addition of Fibreglass tape on the edges for extra edge protection.

Fibre Guard is an entire Fibreglass tape layer applied to the cricket bat for reinforced protection across the face and edges.

Our stickers are unique to us as we make them in-house.

Our UV printing technology mixed with premium vinyls ensure a eye catching finish.

We can even custom make stickers that are unique to your cricket bat.

You can personalise your cricket bat by adding some impressive laser engraving into the face, the back, the edges or where ever you want!

Great for adding initials, a name or some motivational wording.

All bats come with either a white or black chevron grip.

We use these grips as they are super durable and very grippy!

Please get in contact with us if you have

Any questions?

We will help out as much as we can to help you discover what will work best for your game.

Fill out the form, give us a call or jump onto the chat.